Six Degree of Freedom Serial Manipulator

analytical inverse kinematics solution, trajectory planning, testing

Authors: Ahmed Yesuf Nurye, Taye Tsehaye Alamrew, Dilge Vurmaz, Mete Ogulcan Ozduygu

Advisor: Dr. Pawel Maciąg

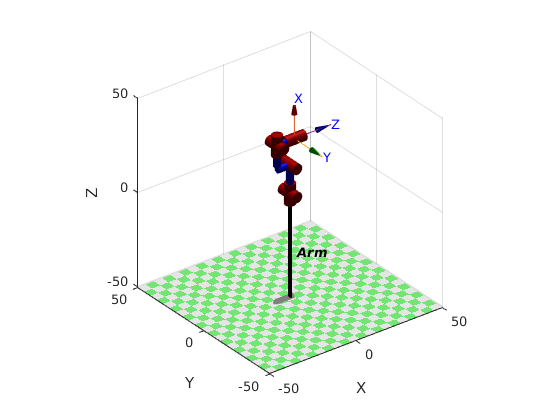

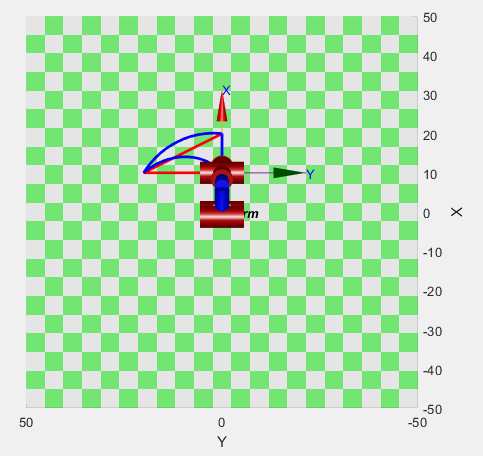

Example simulation.

Abstract

This project presents the design and implementation of a six-degree-of-freedom serial manipulator with a spherical wrist configuration. An analytical solution to the inverse kinematics problem was developed to ensure precise and computationally efficient trajectory planning in both joint and task spaces. The manipulator’s capabilities were validated through simulation and hardware demonstration for pick and place tasks.

Introduction

The aim was to:

- Derive the analytical solution to the kinematic problem.

- Implement trajectory planning in joint and task space.

- Test and validate the solution in both simulated and real environments.

Methods

Kinematic Analysis

- Modified DH Parameters: Used for frame assignments and transformations.

- Singularities: Identified via geometric Jacobian analysis.

The manipulator’s kinematic configuration is visualized below:

Manipulator in Home Configuration (MATLAB Visualization using Peter Corke’s Robotics Toolbox).

Trajectory Planning

- Joint Space (LSPB): Smooth transitions with synchronized joint movements.

- Task Space: Linear interpolation was used to achieve precise straight-line end-effector motion during the approach and retraction phases of the pick-and-place task.

Results

Simulation

- Accuracy: Both forward and inverse kinematics passed MATLAB validation against the Robotics Toolbox with a tolerance of MATLAB’s single-precision floating-point limit (

eps('single')). - Trajectory Planning: Pick-and-place tasks were executed using synchronized joint trajectories.

Comparison of Joint and Task Space Trajectories.

Hardware Implementation

- Setup: Dynamixel servos were configured using MATLAB scripts to ensure precise communication and control of joint motions.

- Outcome: The hardware implementation successfully replicated the pick-and-place task.

Video: Pick-and-place task execution.

Further Reading

For foundational concepts in robotics, refer to the following textbook:

- John J. Craig. Introduction to Robotics: Mechanics and Control 4th Edition, Pearson, 2018.